LiquidSpring’s CLASS system improves the ride and handling of gas-powered motorhomes.

By Mark Quasius, F333630

June 2018

If you love everything about your gas-powered Type A or C motorhome except the ride and handling, you may want to consider LiquidSpring’s CLASS, which stands for Compressible Liquid Adaptive Suspension System. It is engineered to transform a chassis with a leaf-spring system into one that rides more like a high-end diesel pusher with air-ride suspension.

The LiquidSpring strut was conceived more than 20 years ago to fulfill the need for a more reliable and better suspension for off-highway mining trucks. The strut, filled with a pressurized compressible fluid, was able to support the vehicle load and provide dampening. It simultaneously performed the duties of a spring and shock absorber. LiquidSpring later improved upon that concept.

Today, LiquidSpring suspension systems are popular in the emergency services field. Most late-model ambulances are equipped with the suspension, because it provides a smooth ride and stable handling, which allow emergency medical technicians to work safely on patients. The LiquidSpring system also is widely used in the tour bus industry on midsized shuttle buses.

LiquidSpring has expanded into the RV industry and is receiving rave reviews from RV owners. I spent a few days at LiquidSprings’ facility in Lafayette, Indiana, to learn how the system operates, do some before-and-after test drives, and participate in an installation on a customer’s motorhome.

System Overview

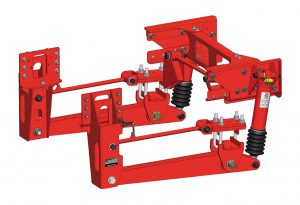

CLASS is not an add-on component that attempts to correct the shortcomings of a leaf-spring suspension. It’s a complete replacement of that existing suspension. On the business end of the system, a pair of hydraulic struts replaces the leaf springs and shock absorbers. The struts, which are filled with a compressible liquid, connect to secondary fluid vessels, which LiquidSpring officials refer to as “volumes.” Valving and sophisticated electronic management change the fluid level in each strut as needed to maintain the correct ride height and to compensate for changes in fluid temperature. A power module contains a pump, reservoir, and valves to supply fluid to the struts and the secondary vessels.

What makes the system work so well is the sum of all the combined components. First, these are not simple struts filled with hydraulic oil. Hydraulic oil does not compress, so there would be zero suspension travel. Instead, the fluid used is a special silicone-based oil that has a 6 percent compressibility factor; this allows the strut to compress to absorb bumps. The fluid lasts forever and need not be replaced during service, nor does it evaporate or absorb water. It’s good to minus 50 degrees Fahrenheit. The fluid can’t be found on retail store shelves, but quart bottles are available from LiquidSpring. Unless you have a leak, you won’t ever have to worry about it.

To provide the proper amount of suspension travel and soft ride, each strut is connected to a secondary vessel, which provides enough fluid for the compression needed. The long, horizontal vessels are mounted alongside the frame rails midcoach and connect to each strut via a high-pressure hydraulic hose.

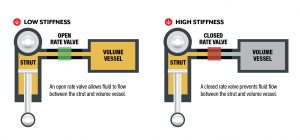

Each vessel has two sections. The smaller portion is connected directly to the strut and is separated from the large primary portion by a rate-control valve. The large primary section is connected to a power supply consisting of a pump and reservoir.

When the vehicle’s ignition is turned on, the system actuates the pump as needed to add pressurized fluid to the struts and vessels until the correct ride height is achieved. Ride-height sensors, installed at each side between the frame and control arms, signal the central processing unit (CPU) once this height is achieved. At that point, the valves close on the power module to hold the captured fluid in the strut and in the vessel, thereby keeping the vehicle at normal ride height. The rate-control valves, which separate the primary and secondary vessels, remain open; they close during driving only when commanded by the CPU. The CPU monitors driving conditions and how the vehicle is being driven. Closing a rate-control valve isolates about 80 percent of the fluid in the vessel from the strut and provides a much higher spring rate than the base spring rate, dramatically increasing the handling characteristics of the vehicle.

What separates CLASS from other suspension systems is its ability to seamlessly change between high and low spring stiffness to provide optimum ride and handling for all road and operating conditions, without driver intervention. The CPU — the brains of the system — makes all components work together.

A driver interface panel, located in the driver’s cockpit area, has settings for ride height as well as ride and handling preferences. The controller keeps the motorhome at the correct ride height when the vehicle is in motion. The RV can be lowered, if desired, to avoid a garage door or other overhead obstructions. This feature must be engaged under 10 mph; the CPU automatically reverts to the normal ride height once 15 mph is reached.

The driver interface also allows the motorhome to be raised in the same manner, which can help prevent dragging the rear of the vehicle on pavement when entering a steep driveway or gas station. The same speed restrictions apply as for the low ride height.

The driver interface has three ride and handling mode settings — comfort, normal, and sport. Comfort mode is the least aggressive, with the primary and secondary chambers in each vessel available to deliver maximum fluid volume to the strut. Sport mode, which is the most aggressive, isolates the primary vessel more often. The CPU pulses the rate-control valve as needed to achieve the best handling and attempt to eliminate the effects from 18-wheeler bow wakes and side winds. It’s all controlled by the CPU. The CPU monitors the ride-height valves as well as the vehicle speed, steering wheel inputs, and brakes.

Let’s assume you perform an evasive lane change when a deer jumps in front of you. The CPU monitors the rate and magnitude of the steering wheel movement and your current speed, and then closes the rate-control valve before the motorhome has a chance to lean. It takes only 40 milliseconds to assess the steering wheel turn and coach speed that may affect body roll and determine that the valve should close.

Once I understood how the system works, I toured the facility and observed the production process. It was apparent that quality control is a LiquidSpring priority. Originally, some processes were farmed out, but they have been brought in-house to ensure that quality can be monitored. Powder coating and baking are done in a state-of-the-art facility. Electrical harnesses are made to exacting tolerances. Everything is tested before being assembled as a kit.

Installing The System

At the normal ride height setting, the distance from the ground to the bottom of the hitch was 23 inches.

Installing CLASS is too complex for a do-it-yourselfer. LiquidSpring’s Lafayette facility installs the system, and the company has selected some independent service centers throughout the United States and trained their technicians to do the work. I observed an installation on a customer’s Newmar Canyon Star.

First, workers raised the motorhome on four hydraulic wheel lifts to allow room to work safely beneath it. Next, to completely remove the rear suspension, the rear of the coach was placed onto a set of tall jack stands. The rear wheel lifts allowed the axle to be lowered so that the springs, hangers, shocks, and other suspension components could be removed. Only the rear antisway bar was retained for reuse.

At the maximum ride height setting, the distance from the ground to the bottom of the hitch was 28 inches.

Large brackets were attached to the frame rails, and control rods were installed to locate the axle. A rear track bar was added. Once the axle was perfectly centered, a bracket was welded to the axle to lock it into place. The control rods and track bar ensure that the axle can move up and down but not forward, backward, or laterally.

Next, the fluid vessels, or volumes, were mounted. Each one previously had been mounted on a hydraulic test fixture, which cycled the system, checked for leaks, and tested the operation of the rate-control valve. The high-pressure hoses that connect the long vessels to each strut were attached. Each vessel was prefilled with fluid and the lines were capped to prevent having to fill and bleed the system later. After brackets were installed for the vessels, the vessels were placed on a transmission jack and raised into position. Stainless-steel mounting bands secured them to the mounting brackets.

Then, the struts were mounted to their brackets. Each strut had been performance-tested earlier and was prefilled with fluid and capped off. Once the struts were firmly in place and the mounting bolts torqued, the hydraulic line that connects each vessel to the strut was installed. Electronic ride-height sensors were mounted to monitor the distance between the axle and the chassis frame.

Next, the power module was mounted beneath the motorhome. Hydraulic lines from the power module were connected to the input connections on each vessel. A ground cable was attached to the frame, and the hot battery cable was run forward to the chassis battery. The wiring harness included a pair of wire bundles to the ride height sensors, which were then connected. A third bundle ran up into the cockpit where it connects to the driver interface control. A convenient spot was identified in the dash, the interface panel was installed, and the wiring was connected. Additional wires were run from the panel to various connections behind the dash for brake and steering wheel position inputs as well as ignition hot power. Workers then tested the system and ran it through its cycles in preparation for the final road test.

Driving Impressions

The difference in clearance in the rear wheel well is noticeable when comparing the suspension at normal ride height, as shown here, to the maximum ride height, below.

For now, LiquidSpring makes only a rear suspension system, but a front-end replacement system also is in the works. Most handling issues begin at the rear axle, so the benefit gained by the current

system is substantial.

It’s important to recognize what LiquidSpring will or won’t do. You still have that same solid front axle, so the pounding from potholes is felt at the driver’s seat. However, passengers in the rear of the RV can notice a tremendous difference. After driving the LiquidSpring-equipped motorhome for a while, I rode in the back and experienced noticeable improvement. Perhaps the cargo benefits the most. Dishes, silverware, and other items don’t bang around, and

the quietness of the drive is apparent in the cockpit.

As soon as the key is turned on, the system pressurizes and achieves ride height. Normally this isn’t necessary, because the system retains its ride height while parked unless you have purposely raised or lowered the suspension.

I tested the RV under a variety of conditions, including quite bumpy, twisting, narrow, blacktop farm roads with many short dips and hills — the kind that lift your stomach as you reach the crest. At a dip in the road, the LiquidSpring suspension didn’t bottom out like the original leaf-spring suspension. Instead, it gradually dampened the downward motion of the coach.

On rises, I found that it performed better than an air-ride suspension on a diesel pusher. Air-ride suspensions are known for a smooth, comfortable ride, but the LiquidSpring suspension more than matched that. When the motorhome encountered one of those tummy-tickling rises in the road, the LiquidSpring system held the length of the strut down, preventing excessive upward travel. A diesel pusher’s air bag won’t do that, so the air bag stretches and extends when popping up over a rise.

I tried out the driver interface, varying between normal, comfort, and sport modes. I didn’t notice any difference in ride quality on normal roads, because the strut just does its thing regardless of mode.

Handling, however, was greatly affected. In comfort mode, the system was slower to respond and allowed the RV to move around more. Switching to sport mode resulted in a quicker and firmer response. Driving along and weaving the wheel in comfort mode allowed the coach to lean from side to side a bit, but in sport mode the lean virtually went away. Sudden lane changes or tight turns at a brisk pace kept the motorhome upright, minimizing the roll that is normally experienced. The solid-axle location of the LiquidSpring system also tightened up any lateral front-end movement.

As noted previously, the suspension can be raised (to prevent dragging the rear of the motorhome) or lowered (to provide more overhead clearance) using the driver interface. Using a tape measure at the test coach’s rear trailer hitch, I found that at the lowest setting, the hitch could drop 5 inches from normal ride height. At the highest setting, the hitch could rise 5 inches above normal ride height. That’s a 10-inch difference between low and high.

To summarize, LiquidSpring’s CLASS suspension offers a major improvement in ride quality and handling for Type A and Type C gas-powered motorhomes with rear leaf-spring suspensions. Adjustments that affect vehicle handling can be made from the cockpit, according to a driver’s preferences or road conditions. The system neutralizes side winds and 18-wheeler bow wakes that can toss a coach around. The result should be less driver fatigue, less wear and tear on the vehicle and its contents, and a more enjoyable driving experience.

Motorhome manufacturers such as Phoenix Cruiser and Chinook are offering CLASS suspensions on their coaches. As an upgrade, LiquidSpring suspension systems are available for the rear axle on Ford E-450, F-550, and F-53 motorhome chassis from model year 2012 to present. In addition, products are also available for most late-model Super Class C Freightliner and International chassis. The cost of CLASS, including parts and labor, generally ranges from $12,000 to $13,000. Contact LiquidSpring to determine whether a product is available for your motorhome.

More Info

LiquidSpring

(765) 474-7816

www.liquidspring.com

Liquidspring Test

SuperSteer, an aftermarket RV parts supplier, tested an RV outfitted with the CLASS suspension system. Read what happened here: https://supersteerparts.com/blog/liquid-spring-rv-test/.