Lithium-iron-phosphate models offer longer cycle life and other advantages.

By Gary Bunzer, Technical Editor

May 2019

RV manufacturers and battery providers have long sought more efficient ways to supply the 12-volt-DC electricity that powers or controls many RV components. The issue is of particular interest to people who dry camp or boondock, untethered from the grid.

For years, the go-to choice for low-voltage power was the flooded, deep-cycle lead-acid battery. It delivers a relatively low amount of current over an extended period (in contrast to an engine-cranking battery, which provides a large, quick burst of power). Eventually, though, the flooded lead-acid battery and the short-lived gel battery were surpassed in popularity by absorbed glass mat (AGM), a sealed-top lead-acid battery. An AGM battery can be mounted safely in any position and charges five times as fast as a traditional flooded battery.

Now, lithium technology — specifically the lithium-iron-phosphate (LiFePO₄) battery — is poised to threaten the reign of the AGM deep-cycle battery in RVs. LiFePO₄ cells initially were developed by a research team at the University of Texas in the middle 1990s.

Indeed, various types of lithium batteries have been around for years. Single-cell manganese lithium-ion and lithium-cobalt-oxide batteries are common in smartphones, computers, tablets, video cameras — even automobiles and hoverboards — but those batteries aren’t suitable for the large loads in RV house circuits.

LiFePO₄ batteries, on the other hand, can be grouped into cells that provide ample voltage and current as consumed by lamps, control circuitry, and motors common to every RV, all within a safe and monitored system. If you’ve seen news footage of a hoverboard bursting into flames because of its lithium-cobalt-oxide batteries, know that this is not a concern with LiFePO₄ cells.

The effectiveness and efficiency of lithium technology make it possible to produce batteries that are half the weight and volume of lead-acid batteries. For example, a single 100-amp-hour lithium battery can replace a 200-amp-hour flooded or AGM two-battery bank.

Another advantage of lithium-iron-phosphate battery cells is their life expectancy — upward of 15 years. Compare that to a 48-month lead-acid battery, which might fail in the 46th or 47th month.

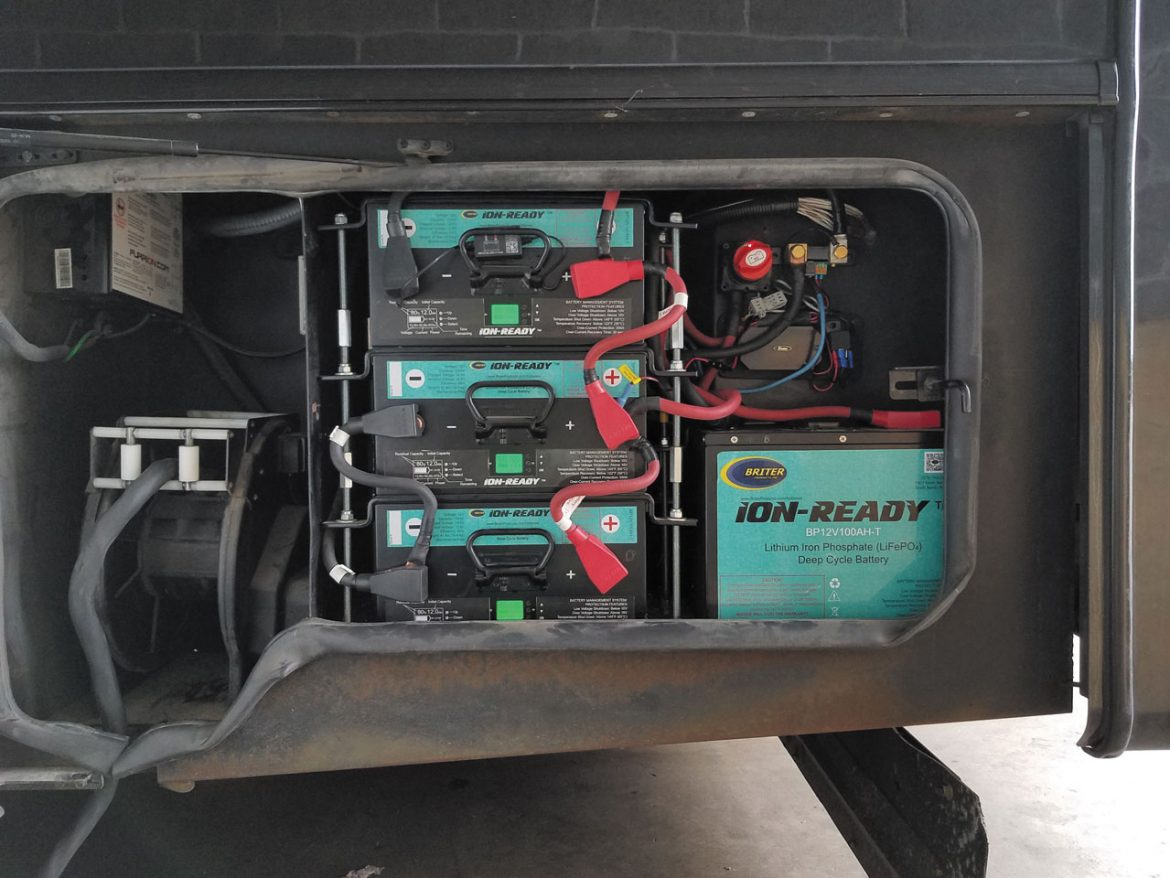

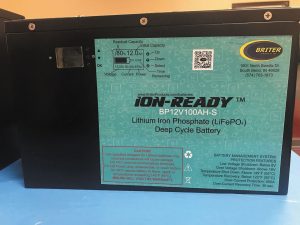

Briter Products Inc., of South Bend, Indiana, is at the forefront of lithium-iron-phosphate battery development, specifically for RVs. The company’s Ion-Ready brand LiFePO₄ deep-cycle batteries include the BP12V100AH-T, which has an LCD display on the top of the battery case to provide an up-to-the-minute, accurate condition of the battery; and the BP12V100AH-S, with the LCD display on the side of the battery case.

Briter’s lithium-iron-phosphate batteries are equipped with a “system of health” LCD display on the top or side of the case.

On both batteries, the voltage, amperage, wattage, remaining capacity, and estimated remaining running time are shown at a glance. “With this information, RVers can monitor their energy usage while making power usage decisions,” said Gyasi Mwewe, Briter’s director of engineering. In other words, gone are the days of guessing how much battery power remains.

The stoutness of an RV battery bank often is measured in life cycles, and this is where lithium technology really shines. A common RV/marine hybrid battery can be deep-cycled approximately 300 to 400 times. A commercial-grade deep-cycle battery can last about 700 to 800 cycles. An AGM battery can live through perhaps 900 to 1,000 cycles (when limited to a 50 percent depth of discharge). But in a system that has been optimized for lithium batteries, a Briter Products LiFePO₄ battery can be deep-cycled upward of 5,000 times (depending on the depth of each discharge) and still have 80 percent capacity remaining. In fact, some lithium cells being tested at U.S. Department of Energy laboratories in New Mexico reportedly have surpassed 7,000 cycles and are still working.

This stems from differences in the way a lithium battery and a lead-acid battery react when a load is applied. Remember, almost every electrical load in an RV consumes the amp-hours stored during the charging cycle. With a standard deep-cycle lead-acid battery (flooded or AGM), the amp-hour rating is based on a 20-hour discharge cycle. But when the battery is subjected to a faster rate of discharge, the actual remaining amp-hours are drastically reduced, and quickly.

Briter’s lithium-iron-phosphate batteries are ensconced in a steel case to protect them against vibrations or impact.

The discharging characteristic of LiFePO₄ battery cells is vastly different. When the battery is under a constant heavy load, the voltage is only slightly reduced throughout the entire discharge cycle. The minimal degradation during charging and discharging cycles is among the factors that make a LiFePO₄ battery bank the most efficient and robust system ever designed for RVs. Such batteries also are considered more environmentally friendly than lead-acid batteries.

Lithium cells are combined in series to provide a nominal voltage of about 12.8 volts DC. Briter’s LiFePO₄ cells are ensconced in a steel case to ensure durability; protect against vibrations or impact; and provide stable conditions for the charging, storage, and delivery of power. To increase battery life expectancy, the internal components of Briter’s batteries are robotically bolted and torqued rather than soldered, since road vibrations can damage or break soldering.

A standard RV converter/charger is not recommended for charging lithium cells, because of their specialized chemistry and electrical requirements. Beware if a supplier markets so-called “drop-in” lithium batteries for an existing RV low-voltage system. The charging device and the matching ecosystem must be engineered to meet the specific charging requirements of the lithium unit. Briter Products has partnered with Progressive Dynamics Inc., a longtime provider of RV converters and battery chargers, to develop a charger designed specifically for the Briter Products battery, as well as other lithium systems. Briter’s batteries can be recharged in two hours or less.

In addition, all RV lithium batteries must be controlled and protected by a dedicated battery management system (BMS). To ensure safety redundancy while using a lithium system, voltage protection is a must. The BMS is the watchdog for system faults such as overvoltage and undervoltage, as well as overcurrent, short circuit, and high-limit temperature protection. To obtain optimum efficiency, the Briter BMS also can record usage data over time.

Briter’s lithium batteries lend themselves for use with RV solar panels. You’ll need a solar charge controller, one that is rated for lithium battery use. If you own an older charge controller, it may be necessary to adjust its charging stages.

RV makers are jumping onto the lithium-iron-phosphate bandwagon, and more are expected to follow as consumers become more educated and demand the best in their RVs. But RVers need not wait. They can take advantage of this revolutionary technology now via the RV aftermarket. Remember, RVing is more than a hobby; it’s a lifestyle!

Briter Products Inc.

(574) 703-1873

www.briterproducts.com

FMCA has partnered with Briter Products to offer FMCA members discounts on Briter batteries. See the “FMCA Update” column starting on page 4 for details.